Liquid Control provides engineered solutions for automated and customized sealant and adhesive applications, including single- and plural-component resin-dispensing equipment for multiple applications, including:Flexible packaging and coating,Gasketing,Bonding,Molding and encapsulation,Sealing, andPotting.

Gasketing,Bonding,Molding and encapsulation,Sealing, andPotting.

Molding and encapsulation,Sealing, andPotting.

Potting.

Contact EnDiSys for accessory questions, additional information or custom design R&D engineering for sealant or adhesive products for motion and automation applications.

Graco Liquid Control™

Liquid Controls from Graco offer high-quality dispensing for a wide variety of materials, including epoxies, urethanes, silicones, heat sink materials, and hot melts.

UniXact Automated Dispensing Solution

UniXact Automated XYZ

Fluid Dispensing System

Precise fluid dispense with XYZ motion for electronics & small part assembly applications.

Single-source automated dispense for tough-to-move materials. The recognized fluid handling experts at Graco have developed UniXact automated fluid dispense solutions built to dispense various kinds of fluid materials for many different applications. Using leading dispense valves for precise, simple, reliable and timely dispensing. The best part is that all of the components are developed and supported by the same worldwide source, a single source turnkey solution.

Benefits of UniXact Automated Dispensing Solutions

Reliability - Consistent dispensing includes the proven Graco fluid dispense technologies to streamline your process.

Precision - Facilitates fast, accurate dispense of tough-to-move materials.

Simplicity - Graco's proprietary software includes an intuitive user interface that provides simple set-up and operation.

Motion Platform

Four-axis Cartesian robot

Overall dimensions

C300 Model

Width: 37 in (939 mm)

Height: 75 in (1905 mm)

Depth: 41 in (1041 mm)

C500 Model

Width: 47 in (1200 mm)

Height: 79 in (2000 mm)

Depth: 47 in (1200 mm)

Work piece area

C300 Model

X: 10 in (254 mm)

Y: 10.88 in (277 mm)

Z: 2.75 in (70 mm)

C500 Model

X: 20 in (500 mm)

Y: 20 in (500 mm)

Z: 6 in (150 mm)

Features

Applications

Automotive Electronics

Mobile Phone

Medical Devices

Industrial Enclosures & Assembly

Printed Circuit Board (PCB)

Other Electronics

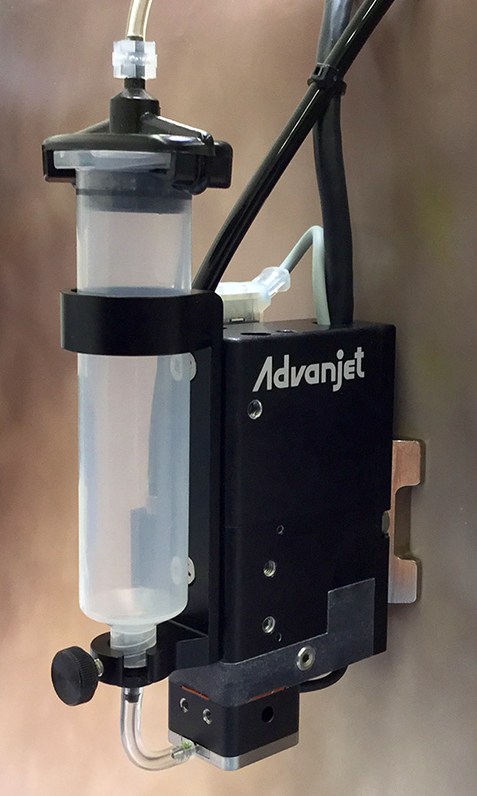

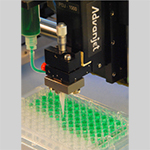

Advanjet Jetting Valve

Precision non-contact

jetting dispense solutions

Graco Advanjet: The global leader and inventor of diaphragm jet technology.

Easy To Maintain

Takes only minutes to clean

Unmached Overall Performance

Increase process window width and production throughput

Low Cost of Ownership

Diaphragm jet design delivers functionality and simplicity

Applications

Assembly/Attach

Conductive Adhesive

Hot Melt Adhesive & PUR

Light/UV Cure

Underfill

Others

Features

HV-2000 Jet

HV-9000 Jet

HM-2500 Hot Melt Jet

Main Office: 14329 Northdale

Blvd. Rogers, MN 55374

Phone: (763) 428-5075

Fax: (763) 428-5078

Illinois Office: 120 Industrial

Drive Gilberts, IL 60136

Phone: (847) 400-4615

Michigan Office: 8408 Saratoga Drive

Lambertville, MI 48144

Phone: (313) 597-5043

Texas Office: 7105 Hunt Lane

Rockwall, TX 75087

Phone: (430) 302-2069