High-volume dispensing demands accurate proportioning and reliability. EnDiSys offers the equipment for dependably transferring, metering, and dispensing sealants and adhesives. In addition to the full Graco product line for dispensing and metering, EnDiSys specializes in designing custom systems for a wide range of applications.

Contact EnDiSys for accessory questions, additional information or custom design R&D engineering for sealant or adhesive dispensing and metering products.

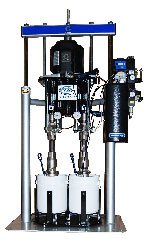

1:1 NXT Extruder

Supply, Metering and Dispense System for Five Gallon (20 Liter) Pails.

Plural component extruder for low-to-medium viscosity paste materials.

The EnDiSys NXT 1:1 Extruder is a fully contained proportioning and dispense system for two component materials used in concrete joint sealing, dowel bar anchoring and general product assembly. This heavy duty extruder is expressly built to handle two component sealant and adhesives within a wide viscosity range at a mix ratio of 1:1

NXT Road Hog Extruder

Supply, Metering and Dispense System for Five Gallon (20 Liter) Pails or 55 Gallon (200L) Drums.

Air-Powered Pump Package For Extruding Silicone Sealants.

The EnDiSys NXT Road Hog Extruder is a fully contained dispense system for silicone sealants used in concrete joint sealing, dowel bar anchoring and general product assembly. This heavy duty extruder is expressly built to handle silicone sealants and adhesives within a wide viscosity range.

Custom HFR Z-Metering Pumps

EnDiSys offers custom metering pumps to give you the freedom and flexibility to mix materials at any ratio and achieve your specific application requirements.

HFR

Graco's HFR Hydraulic Fixed Ratio Metering System processes multiple materials, from rigid and flexible polyurethanes to elastomers and epoxies. Its modular design and precision dispensing capabilities are highly functional; the HFR uses standard parts, available from EnDiSys.

PR 70

The PR70 fixed ratio system accurately meters, mixes, and dispenses two-component medium- to low-viscosity materials for potting, gasketing, sealing, encapsulation, and syringe filling. The PR 70 features a compact, modular design.

Laminate Dispensing

The Laminate Dispense System is designed specifically for dispensing fluids in the manufacture of hurricane glass window and door plants. The unit is capable of flow rates up to 1500 cc/min. and accuracy within 3 cc of desired dispense quantities.

Graco DL

Graco plural component products improve production flexibility, include simple interface software for ease of use, and provide critical process control for precision dispensing and metering. The Graco DL offers accurate continuous flow and shot dispensing.

MD2 Dispense Valve

The Graco MD2 Dispense Valve is designed to accurately dispense and mix plural-component sealants and adhesives with minimal maintenance and cleaning time. The MD2 includes a modular design to adapt to multiple installation needs, and it requires no unique tools for operation or service.

RS Gel Coat Guns

The Graco RS Gel Coat Gun is specially designed for gel coat spraying applications. It is lightweight, ergonomic, and designed for tool-less operation and quick blade changes. Delivers an excellent spray pattern with its Air Assist Containment (AAC) technology.

Gel Coat FRP Systems

Technologically advanced, durable, precise and long lasting. The Graco Gel Coat FRP system is an easily maintained and optimized system for gel coat resin spraying applications. Long lasting seals, pumps that last longer, and no surge bottle necessary means less parts, solvent and resin needed to prime. Comes with the option for DataTrack™ Control.

RS Chopper Guns

The Graco RS Chopper Gun is specially designed for spraying fiberglass reinforced plastics with a mounted fiberglass cutter. It is lightweight, ergonomic, and designed for tool-less operation and quick blade changes.

FRP Chopper Systems

Precise on-ratio dispensing, no surge bottle, low amount of solvent and resin needed to prime, and dual trigger function. The dual trigger function allows for wet-out to chop without removing the chopper. The fiberglass chopper system is for open molding fiberglass and catalyzed resin.

GlasCraft Resin Transfer Molding Systems

Resin transfer molding (RTM) is a closed mold manufacturing process. Finished parts are made by introducing polyester and vinyl ester resins into closed molds containing fiberglass, carbon or other reinforcements. Dispensing equipment for RTM and light RTM applications.

Main Office: 14329 Northdale

Blvd. Rogers, MN 55374

Phone: (763) 428-5075

Fax: (763) 428-5078

Illinois Office: 120 Industrial

Drive Gilberts, IL 60136

Phone: (847) 400-4615

Michigan Office: 8408 Saratoga Drive

Lambertville, MI 48144

Phone: (313) 597-5043

Texas Office: 7105 Hunt Lane

Rockwall, TX 75087

Phone: (430) 302-2069